Optimize the performance of your motion control application by identifying the right attachment method.

Most designers are aware of the importance of torque capacity, torsional stiffness, and misalignment capability when selecting the appropriate coupling for an application. Understanding the various attachment types available to be implemented with a flexible beam coupling is just as important a factor in the decision-making process.

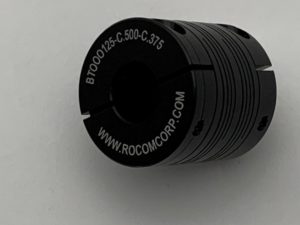

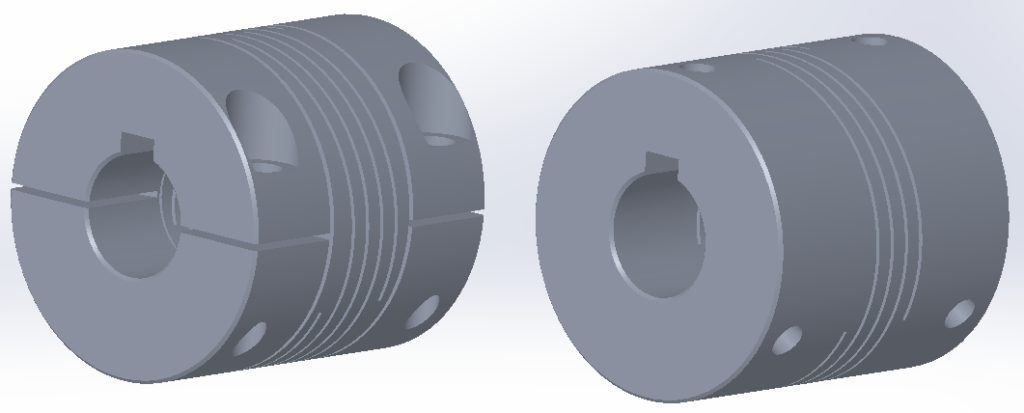

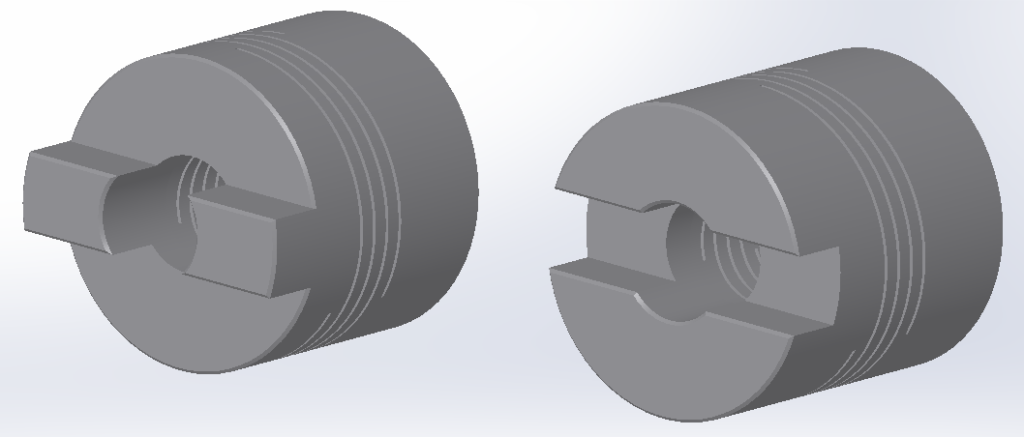

Integral Clamps

One of the most common attachment methods used with flexible couplings. The integral clamp attachment is employed in reversing applications as its positive engagement is difficult to work itself loose. It also does not mar the shaft as a set screw will so shafts can be reused if the coupling is replaced. The integral clamp is created by machining a cross slot across the coupling OD and an end split across the face. A cap screw offset to one side draws down the bore to provide the necessary holding force. The integral clamp is designed so that it will not slip even if the maximum rated static torque is applied. Depending on the location of the cap screw, the head can be recessed in the coupling body or extend past the coupling outside diameter. In the latter case the machine designer must be sure there is enough room in the assembly to accommodate the effective clearance diameter of the coupling plus cap screw.

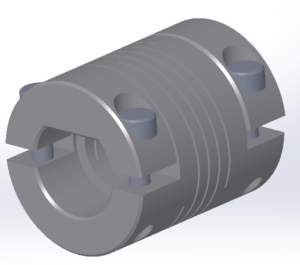

Set Screws

Set screws are the other common attachment method used with flexible couplings. Set screws work best when the shafts have flats machined into them. This provides maximum surface area for the screw to contact the shaft. The set screw attachment works by biting into the shaft material. Set screws are fine for applications where motion is in one direction. When the motion is reversing or subject to frequent stop-starts or vibration, the set screws can work themselves loose. The shaft cannot be reused when replacing couplings as the set screw will permanently displace material where it engaged with the shaft.

Set screws are the other common attachment method used with flexible couplings. Set screws work best when the shafts have flats machined into them. This provides maximum surface area for the screw to contact the shaft. The set screw attachment works by biting into the shaft material. Set screws are fine for applications where motion is in one direction. When the motion is reversing or subject to frequent stop-starts or vibration, the set screws can work themselves loose. The shaft cannot be reused when replacing couplings as the set screw will permanently displace material where it engaged with the shaft.

Cost Considerations

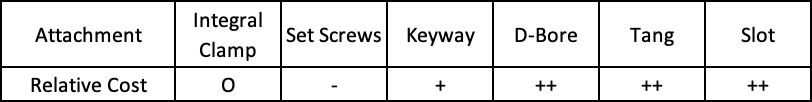

Different features take different processes to produce so cost will vary. The table below gives a rough estimate on the cost differences between attachment styles. An integral clamp since it is the most common is used as the nominal for comparison.

The above examples are just a handful of the types of attachments that can be incorporated into a flexible coupling. Functionality and cost must be considered. Use our coupling selector tool or contact us at [email protected] to assist you in determining the most appropriate flexible helical beam coupling (including attachments) for your application.