Improve the response of your system with torsionally stiff servo motor couplings that dramatically reduce windup while accommodating misalignment.

Employing innovative multiple overlapped helical curved beams, triple start couplings from RoCom Couplings Corp provide a significant increase in torsional stiffness over typical single start couplings

What is a triple start?

A multiple start means that two or more helixes are wound about the same axis. Each helix has the same pitch, pitch diameter, and number of turns. Since each helix is cut into the same coupling, the cross-sections are equal as well. In a triple beam coupling, each start is phased 120o from another which results in balanced, overlapping beams.

.

How does a triple start provide advantages over a single start?

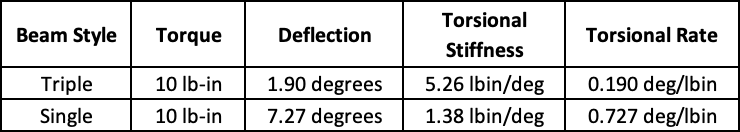

Torsional Stiffness: A triple start or three beam coupling accomplishes this stiffness increase by the additive properties of multiple springs in parallel. If each spring or beam has a stiffness of ki, then the net stiffness is k1 + k2 + k3. Therefore, each individual beam can have a thin cross-section which is advantageous for low reaction forces from shaft misalignment but when used in torsion the effective cross-section is the sum of the individual beams. The table below summarizes torsion tests results between aluminum triple beam and single beam flexible couplings with the same outside diameter, inside diameter, and length.

Balance and Redundancy: As the starts are equally phased around the center axis, triple beams are inherently balanced versus a single beam. Tests by RoCom customers show that when installed correctly, these couplings have a constant velocity.

If one beam were to break the coupling would still function, albeit at a limited capacity. This reduces the likelihood of a catastrophic failure and can allow for replacement at a more convenient time.

Reaction Forces: The most deleterious misalignment for a flexible coupling is parallel offset. Parallel offset occurs when the shaft centerlines are in parallel planes. Tolerance stack-up of mating components is a typical cause of parallel offset. Such a condition results in an elevated stress state which can greatly shorten the fatigue life of the coupling as the stresses alternate during rotation. The RoCom two-set, triple beam coupling accommodates this misalignment with lateral bending as shown in the schematic above. The stress in the coils and the resultant reaction on each shaft is lower under lateral bending as opposed to lateral translation. In a single start coupling, parallel offset is accommodated by lateral translation.

RoCom Couplings Corp designs and manufactures a wide array of flexible helical beam couplings, in both standard designs and custom solutions. Use our coupling selector tool or contact us at [email protected] to assist you in determining the most appropriate helical beam coupling for your application.